Why the Bursting Strength Tester Digital is Essential for Modern Textile and Packaging Industries

In today’s highly competitive textile, paper, and packaging industries, quality assurance is more critical than ever. One of the most crucial parameters in assessing the durability and strength of sheet materials—such as fabrics, paper, and cardboard—is bursting strength. This is where the bursting strength tester digital plays a transformative role, offering precision, consistency, and efficiency that analog methods simply cannot match.

In this article, we will delve into the working principle, applications, advantages, and market relevance of the bursting strength tester digital. We’ll also compare it with traditional systems, explore how it supports international test standards, and show why it is a must-have in quality control labs. We’ll also touch upon mullen burst strength testing—an industry benchmark—to give a complete picture of why digital bursting strength testing is so vital today.

What is Bursting Strength?

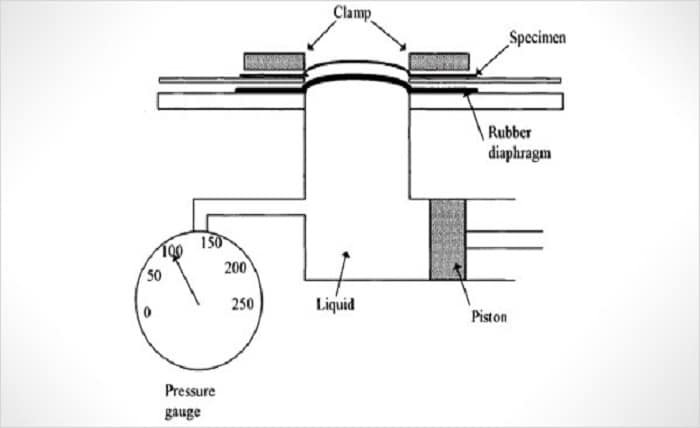

Bursting strength is the pressure required to rupture a material by a force applied via a rubber diaphragm. It is a critical measure of durability, especially for materials that undergo mechanical stress or need to withstand internal or external pressure.

In paperboard and corrugated packaging, higher bursting strength equates to better protection and durability. In textiles, especially technical and industrial fabrics, the parameter ensures that the material can withstand multi-directional stress without tearing or failing.

Understanding the Bursting Strength Tester Digital

The bursting strength tester digital is an advanced version of the traditional hydraulic or pneumatic bursting strength tester. air permeability tester price It automates and digitizes the entire testing process, offering:

- High-precision sensors for pressure measurement

- Digital touch screen interfaces for operation and data visualization

- USB or Wi-Fi connectivity for data storage and report generation

- Compliance with international standards such as ASTM D3786, ISO 2758, ISO 2759, and TAPPI T403

Key Components

- Diaphragm Assembly: Applies hydraulic pressure to the sample.

- Clamping System: Holds the sample securely to prevent slippage.

- Load Cell: Measures the force exerted during the burst.

- Digital Display & Software: Shows real-time data and controls test parameters.

How It Works

The sample is clamped between two circular plates. Textile Testing Machines Hydraulic pressure is applied via a rubber diaphragm until the sample ruptures. The maximum pressure recorded before rupture is the bursting strength. In digital testers, this entire process is controlled, measured, and reported electronically, eliminating human error.

Applications of Bursting Strength Tester Digital

1. Textile Industry

- Testing of woven and non-woven fabrics

- Used in denim, military textiles, parachute fabrics, and industrial filters

- Verifies durability for upholstery and seat belts

2. Paper and Packaging Industry

- Determines strength of kraft paper, corrugated boards, and cartons

- Crucial for food packaging, pharmaceuticals, and e-commerce boxes

- Ensures compliance with shipping and storage standards

3. Leather and Synthetic Materials

- Used in testing artificial leather for shoes, bags, and automobile interiors

4. Medical and Hygiene Products

- Testing materials like surgical gowns and masks for resistance and strength

Why Choose a Digital Bursting Strength Tester Over Traditional Models?

1. Accuracy and Repeatability

Digital testers minimize variation due to operator error. Precise sensors ensure consistent readings, improving test reliability and traceability.

2. Data Management

Modern testers can store thousands of test results and export them for analysis. Integration with Laboratory Information Management Systems (LIMS) streamlines quality control workflows.

3. User-Friendly Interface

Touchscreen displays, pre-set test standards, and multi-language support simplify operator training and minimize error.

4. Compliance and Standardization

Supports multiple testing standards, allowing global manufacturers to maintain consistent quality regardless of production location.

5. Cost Efficiency

Though the initial cost is higher, reduced testing time, fewer retests, and lower manpower requirements result in long-term savings.

Mullen Burst Strength: The Industry Benchmark

The term mullen burst strength originates from the Mullen test method, a widely accepted standard for evaluating the burst strength of paper and board materials. The Mullen test is incorporated into numerous international standards, including:

- ASTM D3786 (textiles)

- ASTM D774 (paper)

- TAPPI T403 (linerboard and corrugated board)

The bursting strength tester digital is often referred to as a “Mullen tester” when used in the context of these standards. However, the digital version provides enhanced features such as:

- Real-time graphical analysis

- Automatic test mode selection

- Enhanced safety features and error detection

These capabilities ensure that the digital tester can perform Mullen-type burst strength tests with higher reliability and faster turnaround.

How to Select the Right Digital Bursting Strength Tester

When choosing a bursting strength tester digital, consider the following key criteria:

1. Test Range and Precision

Ensure the machine covers the pressure range required for your material type. A wide range (e.g., 0–5000 kPa) with high resolution is preferable for diverse applications.

2. Material Compatibility

Look for models that support interchangeable clamps and diaphragms to accommodate various materials.

3. Compliance with Standards

Choose a tester that complies with standards relevant to your industry: ASTM, ISO, TAPPI, etc.

4. Connectivity and Data Output

USB, RS232, or Wi-Fi connectivity is essential for data export and analysis. Look for software integration capabilities as well.

5. Build Quality and After-sales Support

Opt for reputable brands that offer calibration services, user training, and global support.

Industry Trends: Smart Testing and IoT Integration

With the advent of Industry 4.0, smart laboratories are integrating IoT-enabled devices for predictive maintenance and centralized monitoring. Leading manufacturers now offer digital bursting strength testers with:

- Cloud storage for test data

- Remote calibration alerts

- Dashboard analytics for multiple machines

Such advancements enhance the transparency and reliability of quality control systems, especially in large-scale manufacturing environments.

Environmental and Regulatory Considerations

As sustainability becomes central to manufacturing, the need to ensure durable but eco-friendly materials is growing. Bursting strength tests help validate recycled or biodegradable packaging materials. For example:

- Corrugated boards made from recycled fiber must still meet certain bursting strength requirements.

- Medical-grade fabrics must retain bursting resistance even after sterilization or washing.

Digital testers help manufacturers maintain quality while meeting environmental compliance, such as FDA, CE, or ISO 13485 certifications.

Maintenance and Calibration

To maintain accuracy and extend machine life:

- Calibrate the tester periodically using certified weights and tools.

- Replace rubber diaphragms when worn or cracked.

- Keep software updated for optimal functionality.

- Clean and lubricate mechanical parts as per the manufacturer’s guide.

Proper maintenance ensures compliance, especially in audited or regulated environments.

Conclusion: A Smart Investment for Quality Assurance

The bursting strength tester digital is no longer a luxury—it’s a necessity in modern quality assurance labs. Whether you are testing paper, fabric, or synthetic material, this device delivers unmatched accuracy, repeatability, and efficiency. With support for international standards and compatibility with smart data systems, the digital tester significantly enhances your laboratory’s productivity and credibility.

For companies striving to meet global benchmarks like mullen burst strength, the digital bursting strength tester offers an indispensable edge. It not only ensures product durability and safety but also boosts customer confidence and brand integrity.